But let’s not get sidetracked with fond memories of Snapple martinis and mangled clove cigarettes behind the forestry conservation center. My point here is that in addition to being an absolute blast, my trip was both incredibly educational and eye-opening. Because Gene Arganese owns and controls the process beginning with the plants in the fields up to the packaging of the final product, I had a rare insight into the entire process of creating a premium cigar.

Mmm… Corojo…

The Field

You probably wouldn’t realize just how much effort goes into just planting tobacco. It isn’t as simple as sprinkling seeds into the ground and watching for little green signs of life. The plants begin their days in tiny squares of dirt inside a small greenhouse right there in the field. Many of these little plants won’t even make it to the field. Perhaps they’ve grown too quickly. Or maybe they just aren’t keeping up. Either way, the name of the game is consistency. Because out in the field a plant that’s too large will steal sunlight from other plants, and a runt just will just languish in the shade of other plants.

La Flor Arganese: A Pretty Nuisance

Once in the ground, the plants have to be monitored and pruned to optimize the quality of the leaf. Lower leaves on each plant are cut away to maximize the nutrients and growth of the upper leaves. The buds that form likewise need to be removed before they open into flowers to focus the plants growth and energy on the leaves.

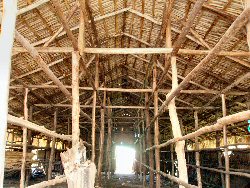

Inside the barn

The Barn

Another thing you might not be aware of is that the majority of tobacco-aging barns in the Dominican Republic are the same. Generally, they’re little more than a roof with supports and bars to hang tobacco leaves for aging. As a result, much of the tobacco coming out of the Dominican Republic tends to be very similar. Gene decided to do things the Cuban way. Instead of using the standard, breezy umbrella design, his barns have walls. And instead of stringing together a single long level of tobacco leaves, he uses a multi-leveled approach to aging. As the tobacco leaves age, they move through the levels from bottom to top. This process ensures both consistency in the fermentation, and cleverly dries and then rehydrates the leaves naturally.

And the drying begins…

The Factory

I’ll be honest with you. The process of fermenting the leaves is so involved, that even though I saw it from end to end, I couldn’t tell you how to reproduce it. There were just too many stages of sorting, aging, rotating for me to accurately report. I was surprised and impressed by the care and attention paid to the leaves as they made their way to the bale. I counted no fewer than four different aging areas the tobacco visits before it is pressed into a handy little cube and delivered to the rollers.

These leaves still have a way to go!

This might sound excessive, but then you probably haven’t stepped into one of these aging rooms. In the factory, Cristobal, Gene’s right hand man, has a running bet with all visitors. He’ll give you a hundred dollars if you can stand in the final aging room for five minutes. About 30 seconds into it, you’ll understand why. The air is thick with ammonia that is slowly leaving the leaves as part of the fermentation process. Standing that room for even a minute is a little like trying to polish your lungs by inhaling Windex.

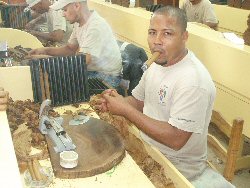

A master roller creates rolls blends we created!

The Rolling Floor

Of all the stages of the cigar creation process the actual rolling of the cigars is the part that people are most familiar with. The Arganese rolling process is much the same as you have probably seen before in videos or rolling demonstrations at your local smoke shop. The filler leaves are bunched and wrapped with the binder leaf. The cigars are put in trays and pressed into shape. Then the wrapper is applied and set aside for inspection.

Oodles of Double Wrap Chairmans…

But there’s one thing that makes this process a little unusual. Gene is very protective of his blends, and as a result, the rollers don’t actually know what tobacco they’re using to create the cigar! That may sound hard to believe, but it’s true. Each roller (torcedor) is given a measured allotment of leaves in a bag that’s good for a certain number of cigars. When the torcedor has finished making the designated number of cigars, he or she returns with the bag and the unused tobacco. In addition to keeping his blends a secret, this process functions as part of quality control. If the torcedor brings back too much tobacco of one kind of tobacco or another, there’s a good chance the cigars rolled will be incorrectly blended.

Hard to beat having a fresh smoke on the job!

Once the cigars are rolled and approved by the master Torcedors who monitor the rolling floor, the cigars are sent to yet another two again rooms to allow the blended tobacco to marry flavors before they are cellophaned and boxed. These additional two stages of aging may seem like overkill, but they’re absolutely necessary. To begin with, a surprising amount of ammonia and other unpleasant chemicals are still in the leaves, even at later stage. Though walking into these aging rooms wasn’t quite as hard on the respiratory system as earlier ones were, the air is still very full of these unwanted elements. Additionally, the humidity levels of the different tobaccos (filler, binder and wrapper) are very different when they are rolled.

Estimated Tobacco Humidity on the Rolling Table

Filler – 35%

Binder – 80%

Wrapper – 95%

The much anticipated CL3‘s

The Cigars

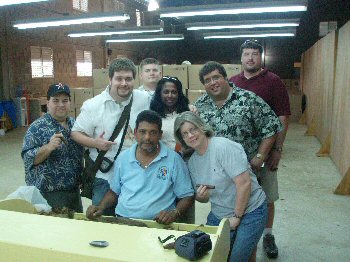

After viewing the lengthy process of transforming a the large green leaves of the tobacco plant into the a fine handmade cigar, one can’t help but have a great deal of admiration to the lit cigar in your hand. And I had plenty of opportunity to admire the end product. I’m incredibly grateful to Gene Arganese for putting us up and taking the time to show us his facilities.

I went to the Dominican Republic knowing next to nothing about Arganese cigars, and I returned a diehard fan with boxes (and some newfound knowledge) in tow! And now, I believe it’s time for a Maduro Chairman. Long ashes!

The CigarLive Group

Looks like you guys had a great time. Very cool of Gene Arganese! That was a trip of a life time.

You’re right Stinkie, it was the trip of a lifetime. Of course, I’m greedy, so I hope to go on more trips-of-a-lifetime in the not too distant future.

Gene is an great guy. Not only does he make a great cigar, he’s also the kind of guy you want to drink a beer and smoke a cigar with. And we did.

What a great experience it must have been. I harbor feelings of jealousy at the moment 😉

Brian-

My buddy and I have started a cigar representation business and we plan on having Arganese as our signature brand and can’t wait to get these sticks into the Upper Midwest shops soon! I am curious how you came upon this trip…you must rate pretty damn good to get an invite to Arganese in the D.R. Did you have to pay your own way or was it a flat out treat from Arganese?

It was great, Tom. Absolutely excellent. And I didn’t even mention the girls in this post. But I better hold off- I don’t want that jealousy building into rage! (Hey wait, is that Tom I see out there in the bushes? What the…. Ahhhh!) LOL

Joe,

Well, my reviews have been known to make or break an entire line of cigars! (In my dreams, that is.) Actually, Gene made this offer to all members of the CigarLive form ( consider joining!). I happened to be one of the few in the right position to travel, and the willingness to do so at the drop of a hat. (It pays to have your passport! And it helps to be a travel nut.)

I had to pay for my flight, but everything else was covered. I know the CigarLive forum founder, Daniel was 100% covered for his earlier trip. (He also happens to have a good deal of clout in the industry.)

What I’d recommend to you is give the Arganese office a call. I know Gene is bringing in a lot of people up until sometime in April. You may be able to work out the same deal I had if you ask!

Brian – Obviously you’ve seen my videos, and realize I am a creepy bastard. Feel free to share the entire story though, I’m feeling much better today 😉

Awesome stuff Brian, did the Generalissmo park his helicopter next to the box factory when you guys visited as he did when we were down there?

Thanks Daily Doormatt,

Nope, I can’t say we had that pleasure. I take it you did when you were down there? I gotta say, that is a pretty interesting arrangement Gene has worked out down there though.

Bravo Brian!!! You did an EXCELENT job on your report from your field trip.. Haha. Thanks for making our job of selling cigars easier, simply by your pics and thorough explainations!!! Great job!! I bet u will have an endless supply of Arganese Cigars!!

Thanks Cigar4u,

I won’t lie, I do have a nice selection of Arganese cigars. LOL I’ve sorta been hording them, because they aren’t yet available for sale in Hotlanta. I’m on a one man mission to change that. (Reportedly orders have been made. I’ll believe it when I see it!) Good luck with the sales!

Beautiful pictures man.